Pre-insulated aluminium sandwich panels of rigid PIR foam 35kg/m³ density, blue color and 20 or 30mm thick coated aluminium sheet embossing 0.06mm (60mμ) on both sides destined to the manufacture of HVAC ductworks of low and medium pressure.

Other combinations between foam density, aluminum type, thickness and panel length are made to order.

PIR-ALU® is a registered trademark of KINGSPAN INSULATION, S.A.

piralu.com

kingspanaislamiento.es

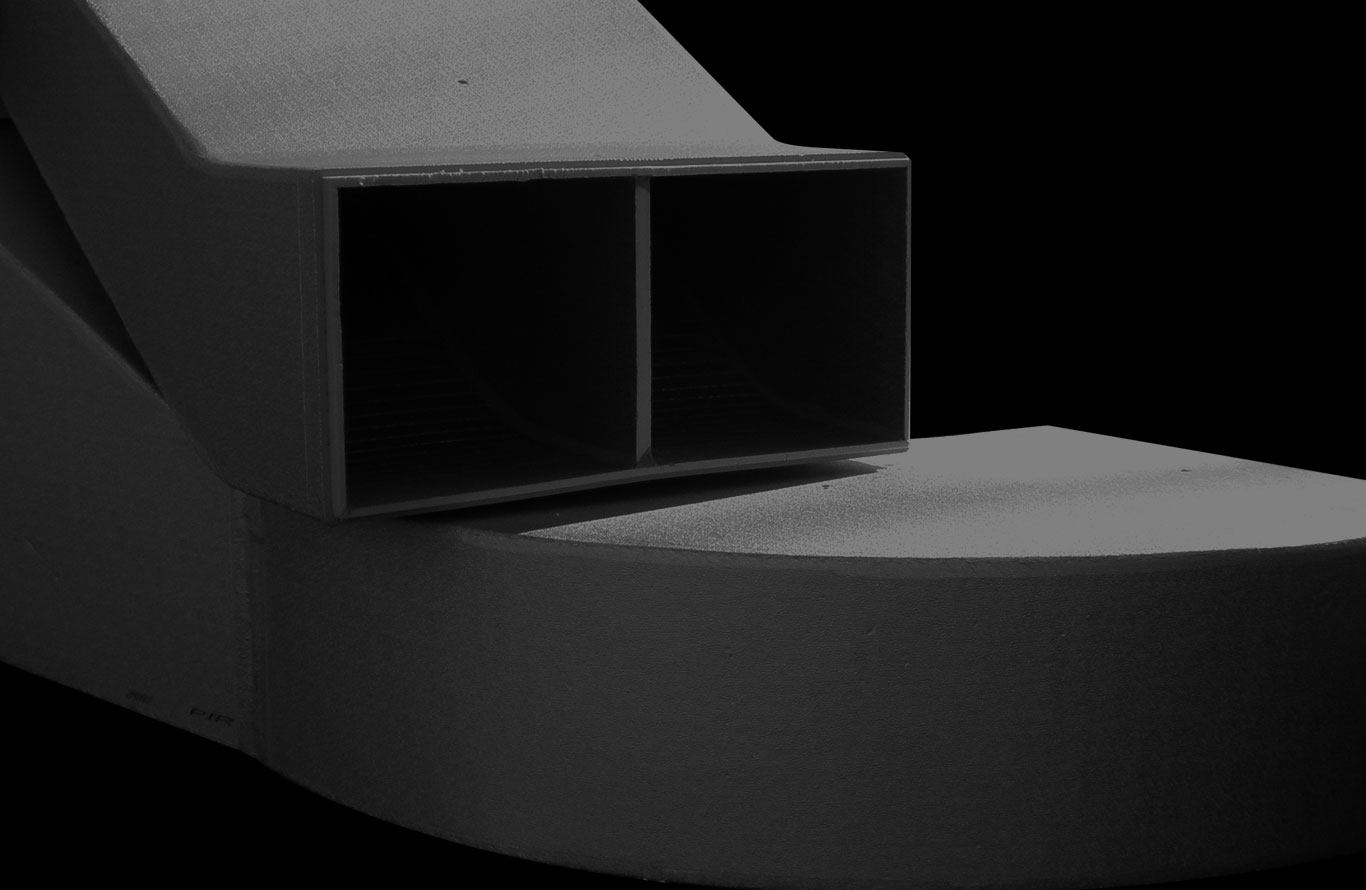

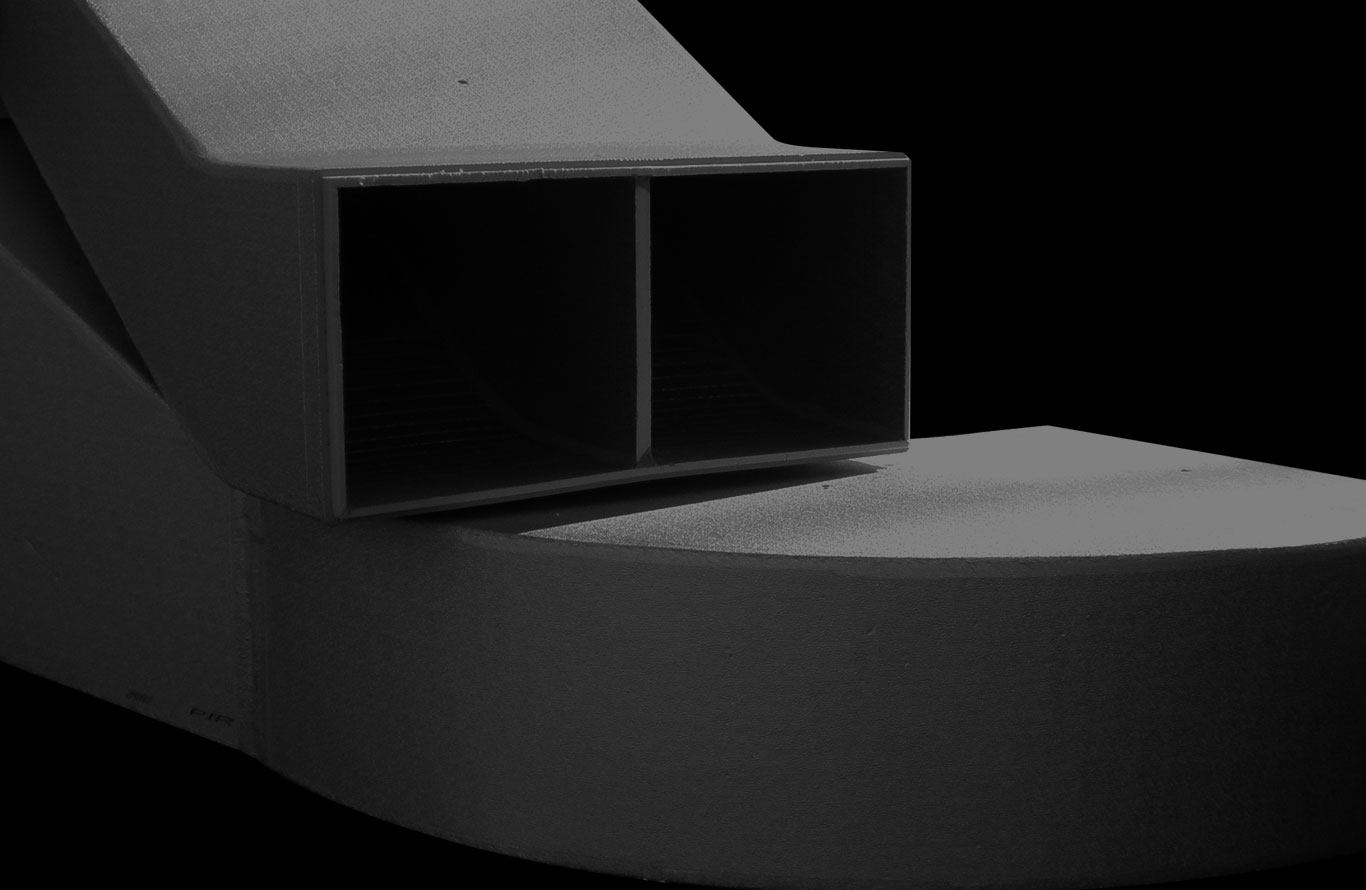

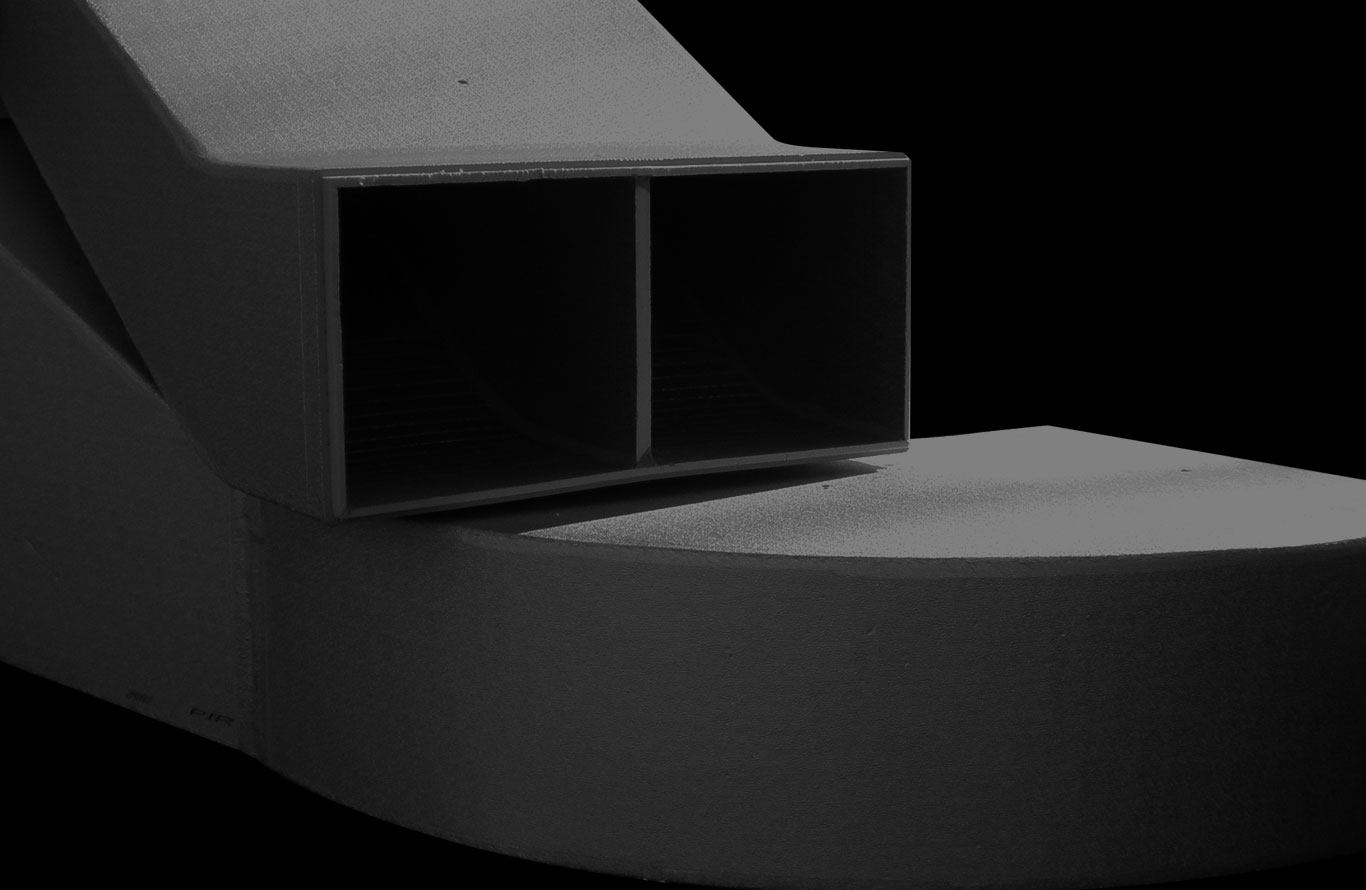

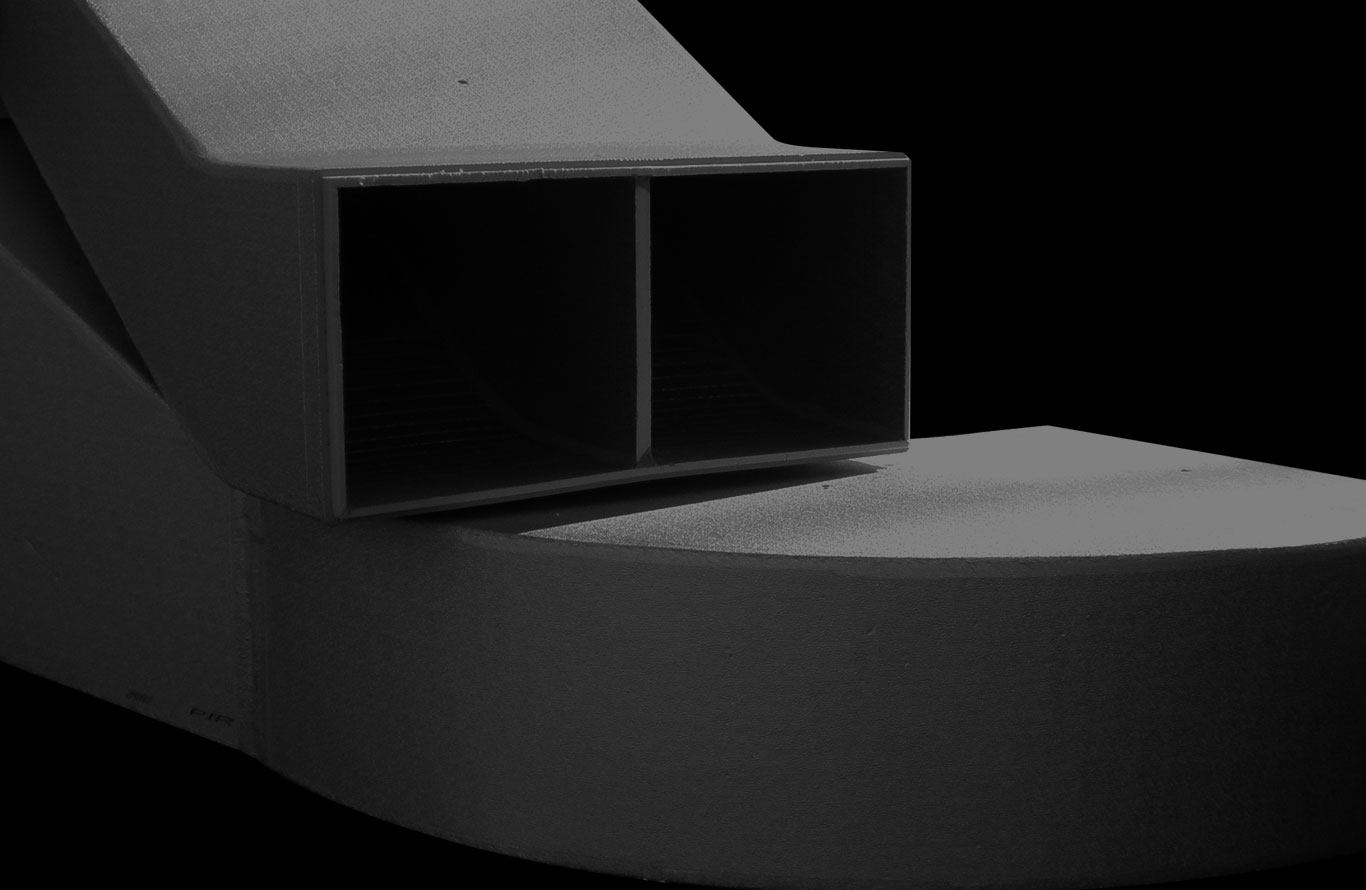

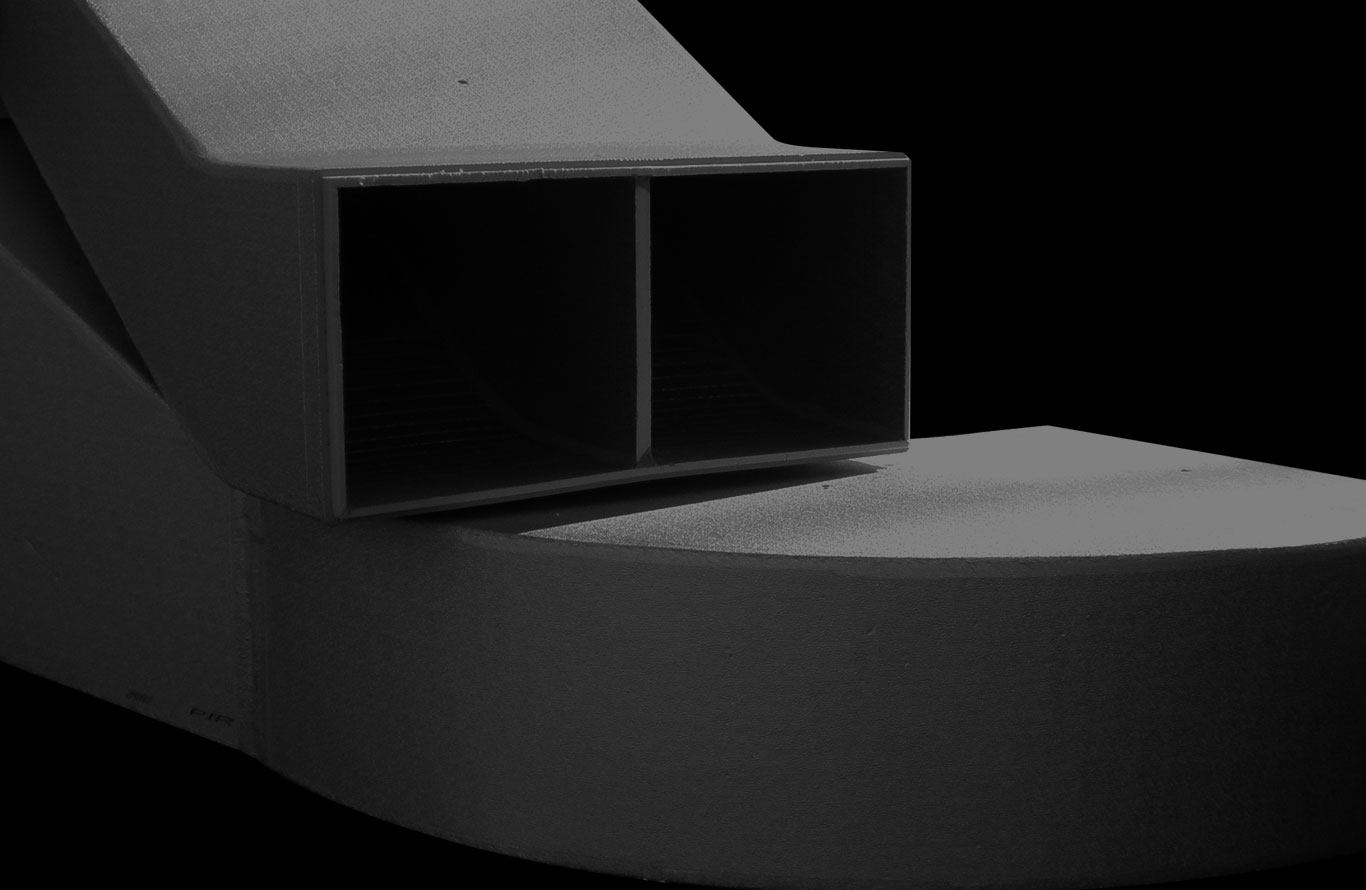

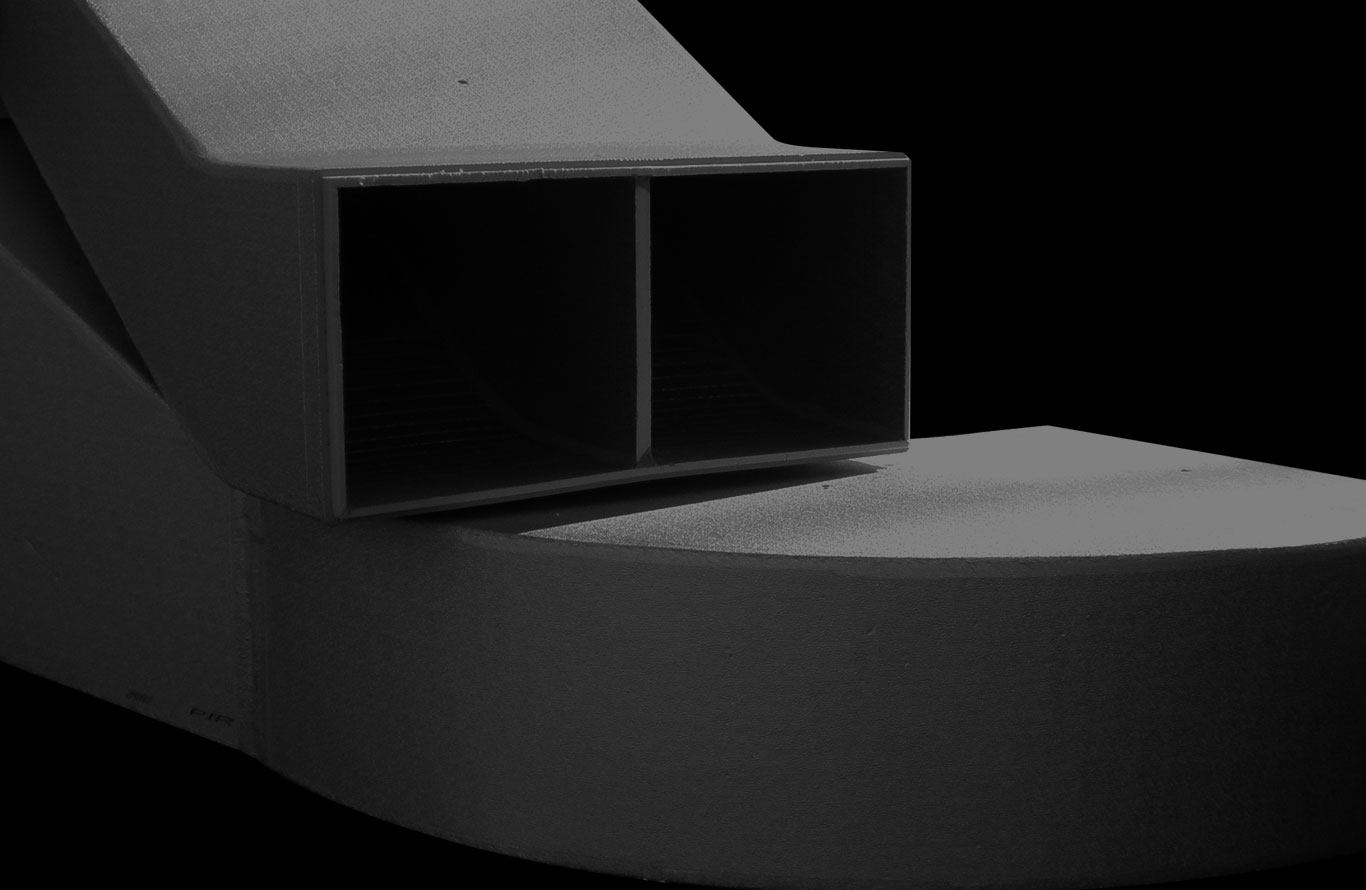

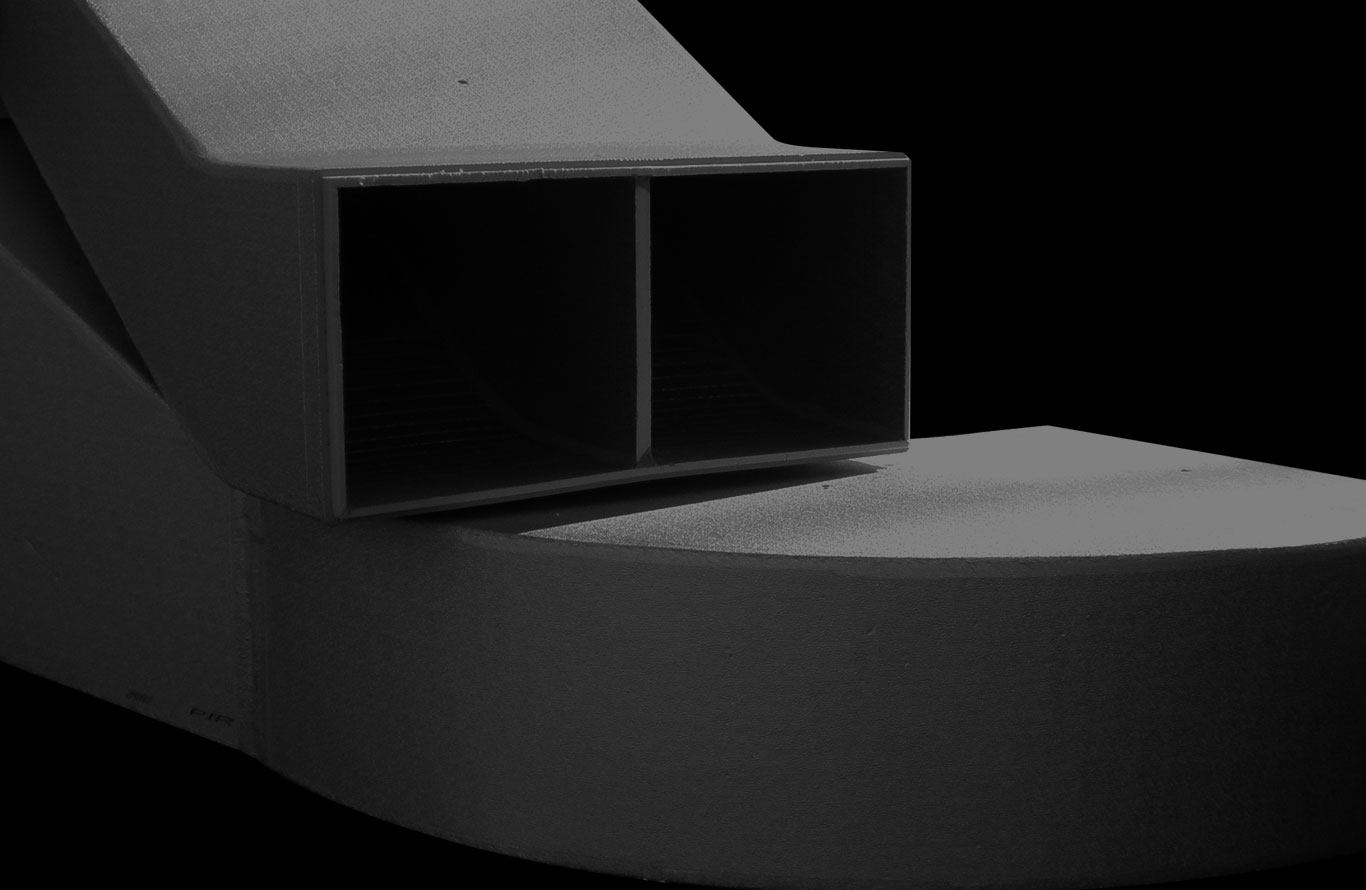

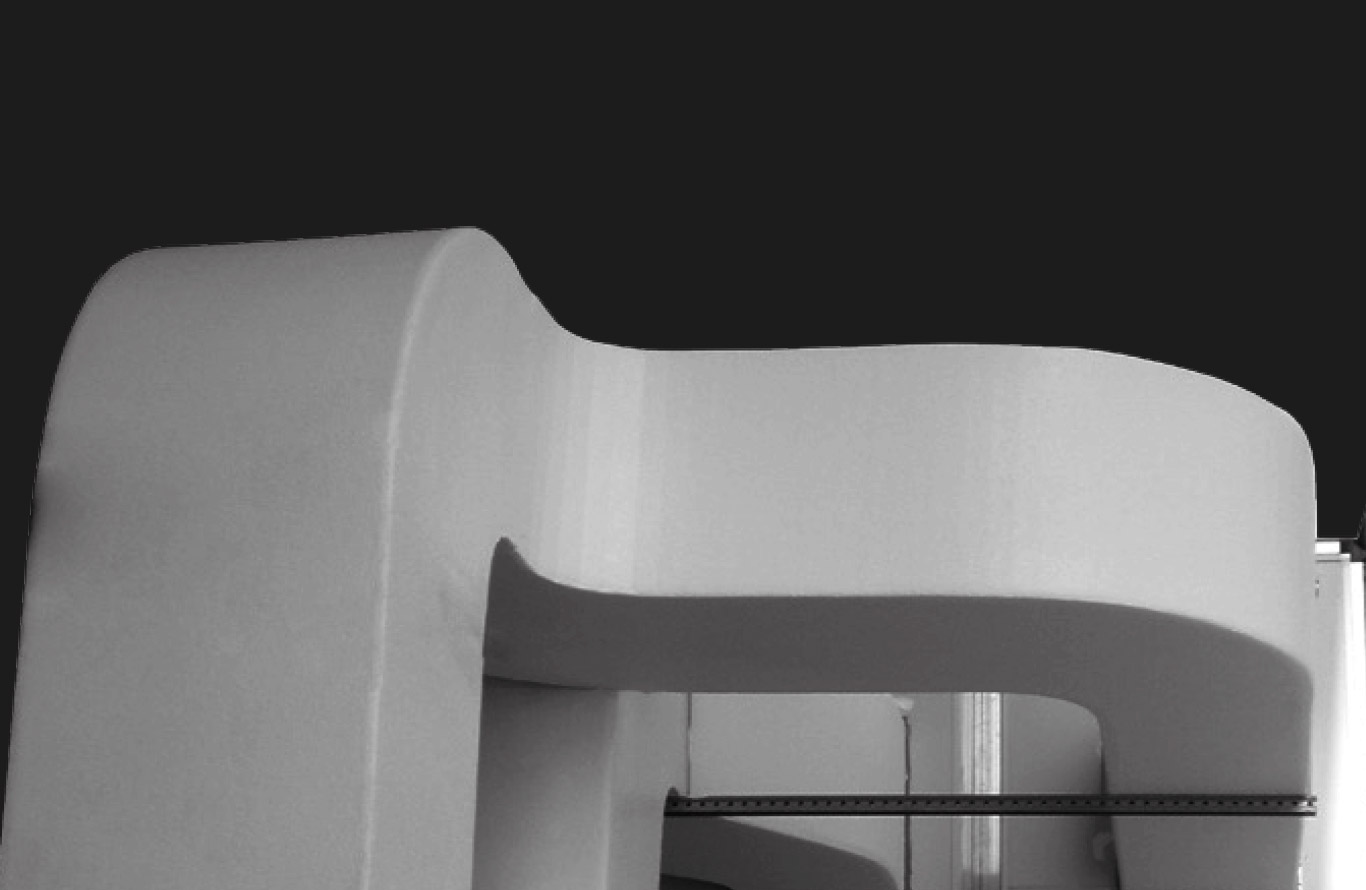

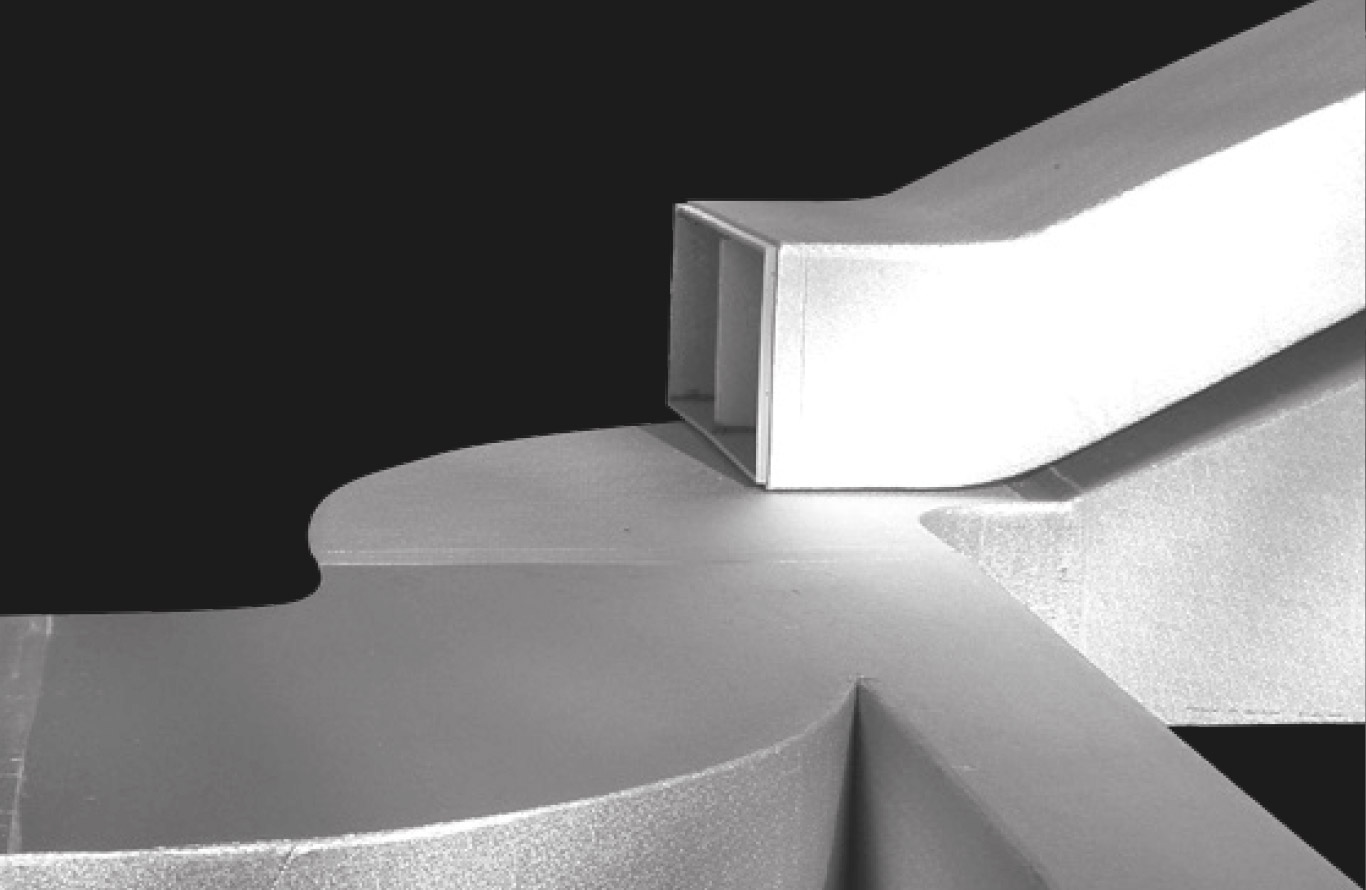

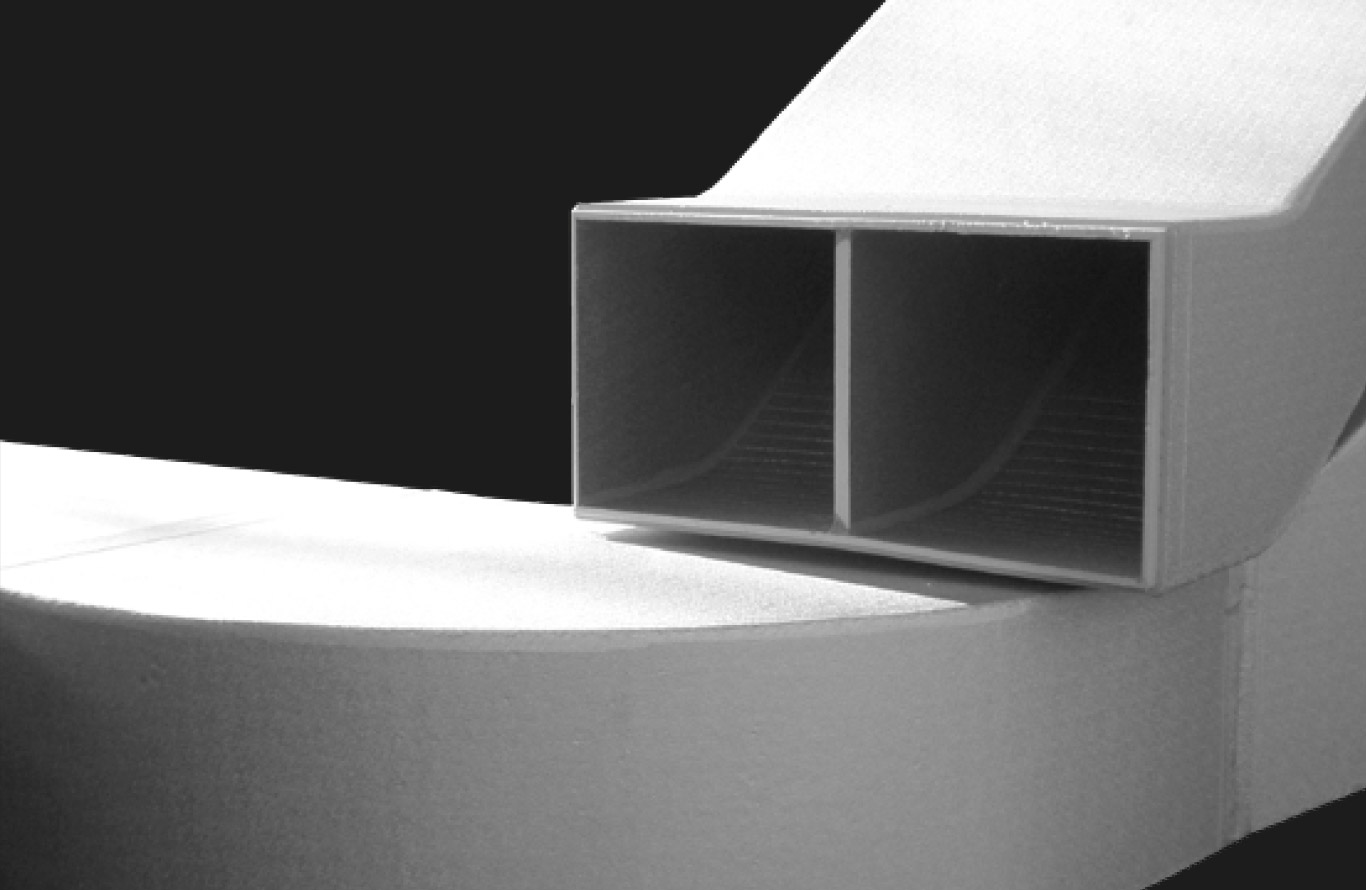

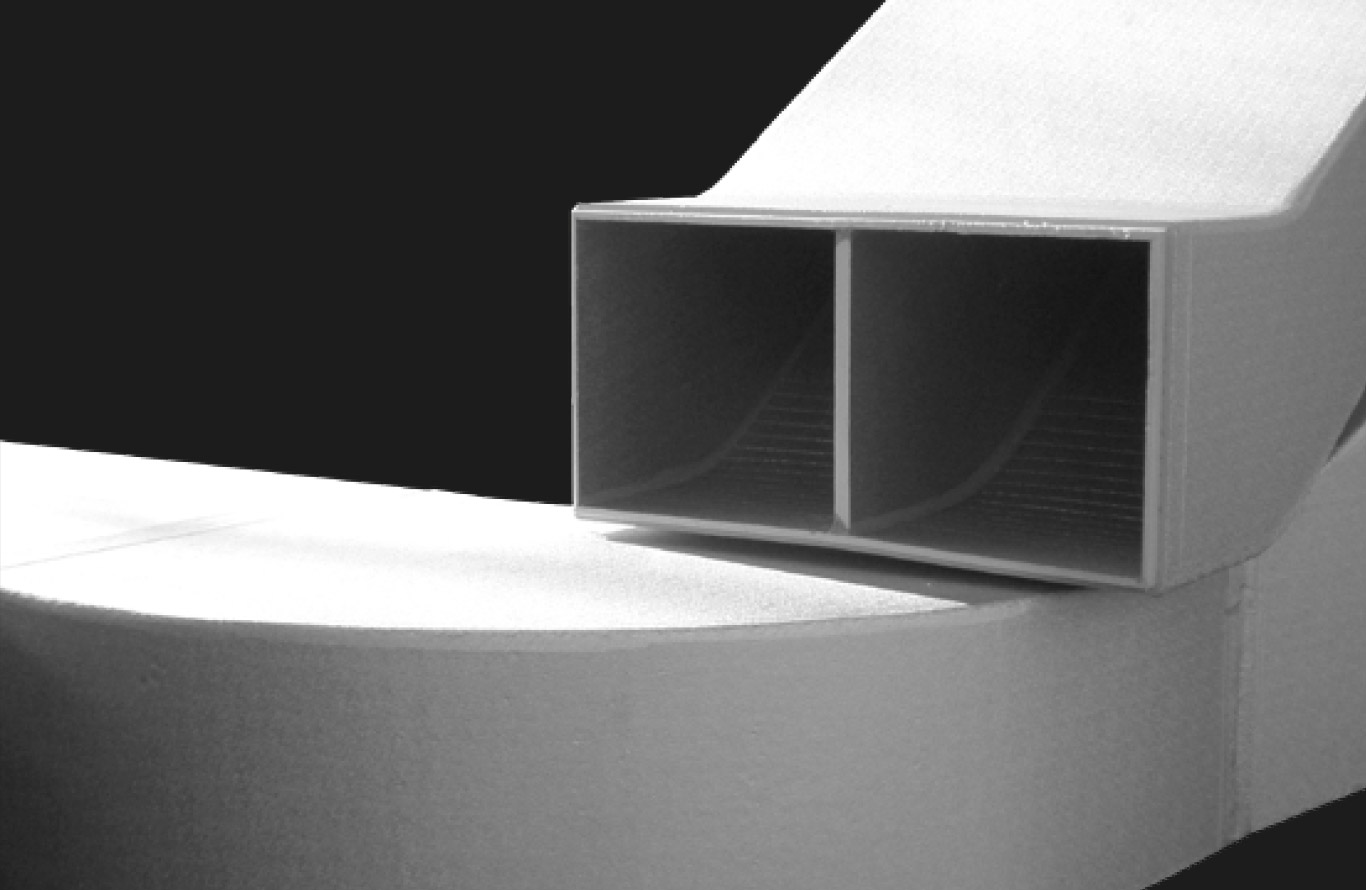

Process of transformation of the PIR-ALU panels in HVAC air ducts.

STRIP SYSTEM® is a registered trademark of STRIP SYSTEM, S.L.

strip-system.com

In PIR-ALU we know that who buys panels are buying air ducts for over thirty years in PIR-ALU constantly we think how to make the best panels and STRIP SYSTEM on how to simplify the process of transformation of the panels in air ducts.

Competitiveness. The constant analysis of how they have evolved regulatory requirements and technical needs of the air ducts has helped us to detect, anticipate and provide the most rational and relevant solutions.

The origin of this type of panels for the manufacture of ducts is dated 1973 when the Spanish company PRAXA (KINGSPAN GROUP) developed a product fill a needs that had been detected in those years an new and growing market as was the air conditioning.

His contribution was a panel that could be formatted and easily build various forms and measures required for ductwork with sufficient rigidity to support its own weight and air pressure, with insulation that will prevent condensation and ensure the indoor air hygiene.

Middle of the decade of the 70 other especially Italian companies had also detected these same needs were interested in this idea and adapted it and were evolving in terms of regulations and subsequent requirements.

The good reception given to this type of duct panels has been due to its good technical performance and practices and the growth of the air conditioning market over the years to have become a standard.

The air conditioning is an artificial system of regulation temperature in an enclosed space.

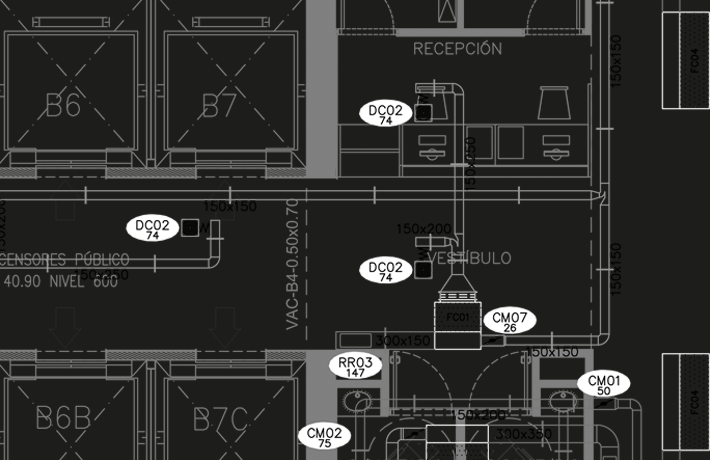

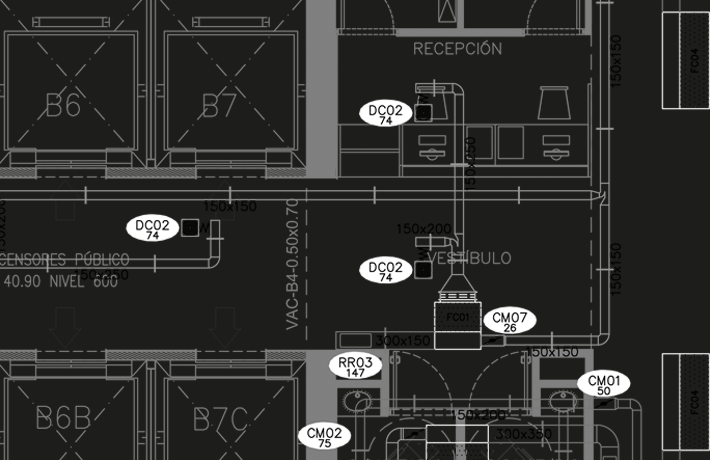

The basic components of an air conditioning system are the A/C unit (UMA or conditioner), the ductwork and the terminal units for distribution and diffusion of the air.

The fan of the A/C unit generates the required air flow.

The ductwork carry and distribute air between different areas or rooms of a building.

The components like grills and diffusers regulate the amount and scope of air in the atmosphere of the rooms.

The necessary requirement of the circumstances and conditions which is intended ductwork, regardless of the material it is constructed, the air duct must be:

The ducts built with PIR-ALU pre-insulated aluminium panels are specially designed and evolved in line with these requirements and needs by providing high added value to the ductwork without being penalized financially.

Standard dimensions and shapes.

The key to competitiveness is to know the cost before starting work.

In practice it is very much like a DIY. (Do It Yourself)

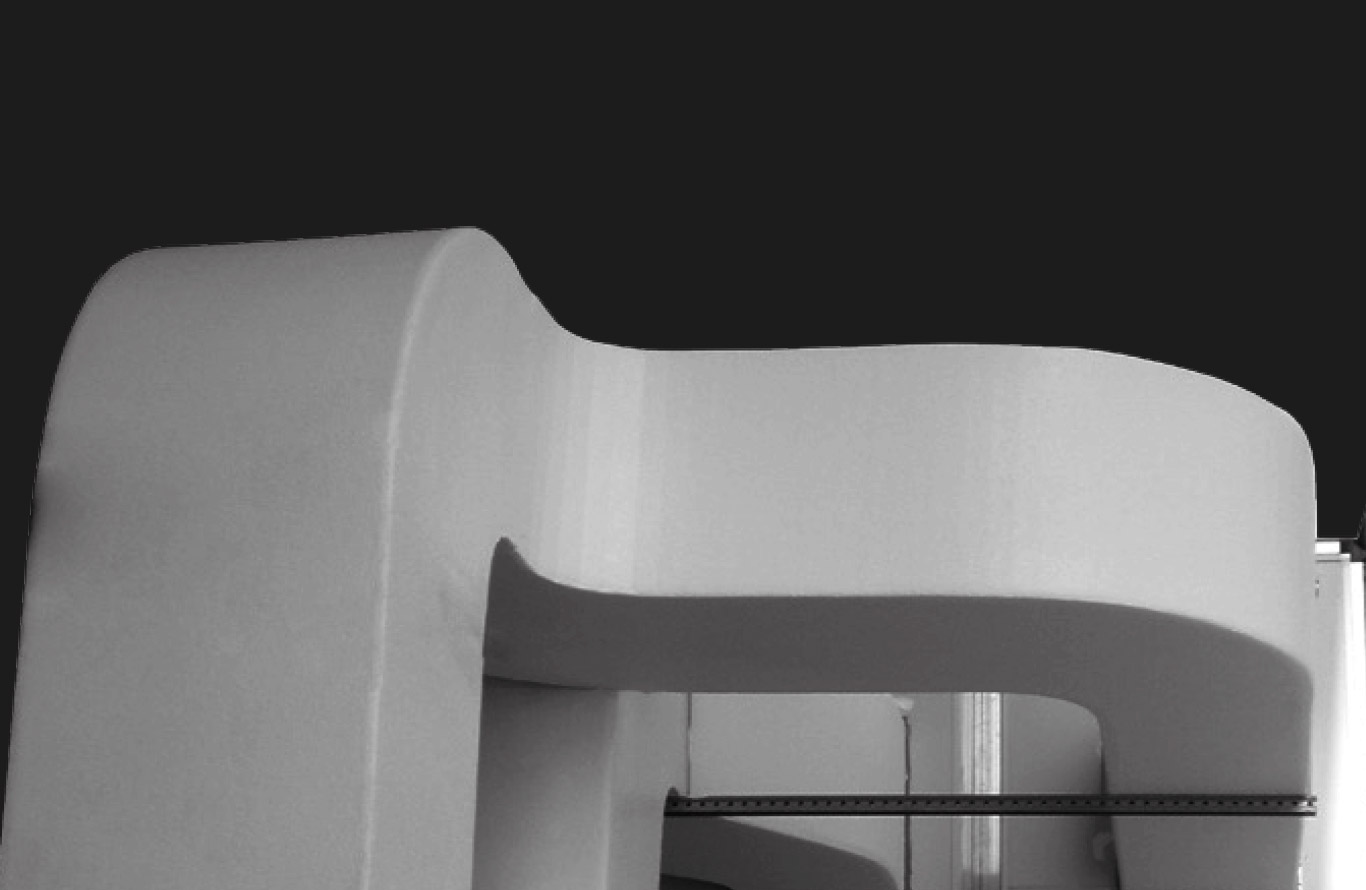

It is installed at high speed, it requires few supports and air ducts are assembled in sections 3 or 6m long. The PIR-ALU ducts weigh only about 1,1 kg/m².

Once installed, the air ducts are very nice to see, harmonic and proportional.

It can be installed inside and outside of buildings. In hospitals, residential, commercial, industrial buildings, etc …

Free and exempt of risk.

Meets the highest international requirements of mechanical resistance and reaction to fire.

Avoids any risk of condensation.

All features of materials and finished air ducts are credited with tests and certificates required by the regulations, rules or standards and certifications.

The combination of the best thermal insulation (λ=0,023 W/m·K declared according EN 12667), the low load loss (absolute roughness: 0,03mm) and the highest rated sealing duct low and medium pressure (EN 1507: class “C”) translates into savings of many kw energy throughout the lifecycle of the facility or LCC. (Life Cycle Cost)

It is small cost and requires little expense.

Legal requirements, standards and applicable specifications

The standards and regulations establish the energy efficiency, environmental and safety requirements that must be met by the duct networks in buildings to meet the demand for comfort, well-being, hygiene and health of people.

Thermal insulation

Air tightness

Load loss

Shapes and dimensions

Respectful

Ecological

Sustainable

Reaction fire

Mechanical resistance

Reduced weight

Seismic restraint

The aluminium

Microbial growth

Facilities for cleaning

Facilities in Hospitals

Air ducts made with PIR-ALU pre-insulated aluminium panels cover widely the required expectations for their use.

Not all pre-insulated aluminium panels or air ducts after completion meet the technical requirements required.

The performance of materials and finished air ducts are credited with tests and certificates.

EUROPEAN CONFORMITY MARKING

The implementation of EU Regulation No. 305/2011 of the European Parliament establishes that for marketing materials for construction the products to be marketed in the scope of the EU must have the CE mark.

The purpose of the regulation is to define the conditions for marketing construction products by establishing harmonized rules on how to express the performance of these products in relation to their essential characteristics, while giving instructions on how to affix the CE marking on those products.

The presence of the CE marking on the label, packaging or delivery note of the construction product means that the manufacturer has declared a number of benefits for your product, that transfer to the market through a document called declaration of performance (DoP) that is their responsibility to have carried out the tasks laid down in Regulation and the harmonized standard for each product.

“Thermal insulation products for building equipment and industrial installations. Factory made rigid polyurethane foam (PUR) and polyisocyanurate foam (PIR) products. Specification.”

This European standard specifies requirements for manufactured products of rigid polyurethane foam (PUR) and polyisocyanurate (PIR), containing not less closed cells 90%, with or without coatings, which are used for thermal insulation equipment in buildings and industrial facilities working temperature range of approximately -200 ° C to + 200 ° C.

The products are manufactured in the form of blocks, panels with or without coating, shells, segments and prefabricated elements.

This standard describes product characteristics and includes test methods, evaluation of conformity, marking and labeling.

PIR-ALU panel is a coated board and has the certificate of declaration of performances of the product (DoP) according to EN 14308.

Regulation of Thermal Installations in Buildings, RITE, establishes the requirements for energy efficiency and safety to be met by thermal installations in buildings to meet the demand for welfare and health of people in both phases of design, sizing and installation, and during use and maintenance.

Thermal Facilities fixed air conditioning systems (ventilation, cooling and heating) and hot water production for sanitary purposes, designed to meet the demand for welfareand health of people in all types of buildings, including industrial buildings are considered.

For full compliance with European Standard EN 13403: “Ventilation for buildings. Non-metallic ducts. Ductwork made from insulation ductboards” must certify the following tests and requirements:

ASHRAE American Society of Heating, Refrigerating and Air-Conditioning Engineers

Energy Standard for Buildings Except

Low-Rise Residential Buildings

Ventilation for Acceptable Indoor Air Quality

Thermal Environmental Conditions for Human Occupancy

HVAC Design Manual for Hospitals and Clinics

Practical Guide to Seismic Restraint

The PIR-ALU air ducts meet these standards and other relevant ASHRAE.

The PIR-ALU air ducts add value to the following LEED credits:

Complies with ASHRAE Standard 90.1 for efficient use of energy.

Full implementation of regulations and rules or international standards.

Reduce energy consumption.

Excellent thermal insulation.

Optimal air tightness.

Protection for non-microbial growth.

Optimal acoustic behavior.

Materials with low emission of volatile organic compounds (VOC)

Eco-compatible materials.

Reducing waste in the manufacturing phase.

Minimize and control the waste made in the workplace.

Inert waste.

Environmental Product Declaration EPD-LCA (Life Cycle Assessment).

Standardization of the dimensions and shapes of the ducts.

Very significant reduction of waste.

Analysis of the Life Cycle Costing of the facility (LCC).

A product and a very useful system

Certified Company:

Management Systems Quality

Environmental Management Systems in the Organization

Systems Safety and Health at Work of the Organization

Enviromental Product Declaration

PU Board with aluminium facing

The manufacturing process is not harmful and is environmentally friendly.

It rationalizes and reduces energy consumption.

It is clean and healthy to work.

Does not harm the health of people and their work environment.

It maintains clean and hygienic ductwork and indoor air quality (IAQ) protecting the health of users.

PIR-ALU is a product manufactured in the EU by KINGSPAN INSULATION, S.A.

The manufacture of the PIR-ALU panels is made and obtained without using any chemical compound that damages the environment.

Free of CFC and HCFC.

Fully comply with the provisions of the Kyoto and Montreal protocols the framework convention of the United Nations climate change.

Residues produced in the manufacture of the panels and the waste generated during the manufacturing process of the ducts is considered inert waste as it is a non-heavy metal (aluminium) and a plastic.

Protect and advance the natural resources and protect the environment from harm or danger is our generational duty and this must be our legacy to the future.

The manufacture of the panels does not harm natural resources or cause environmental damage.

Thanks to the performance and features of the PIR-ALU panels and the transformation process of the panels in air ducts, PIR-ALU contributes significantly to get the appropriations in the LEED standard and works to make projects more eco-sustainable.

The isolation prevents heat transmission.

The core of panels is a PIR (polyisocyanurate) rigid foam insulation of density 35kg/m³.

The low density of the PIR foam has excellent thermal properties.

Thermal properties according EN 12667:

The aluminum coating thickness >0.04mm (>40μm) on both sides guarantees the vapor barrier.

At the present it is one of the best thermal insulation available on the market.

Compared to the traditional thermal insulation of fiberglass the PIR-ALU ductwork reduces the energy consumption by ±25%.

La classification de la rigidité du panneau selon EN 13403 est pour 20mm d’épaisseur classe “R4″ ” (Nmm² 200.000) et supporte des pressions positives ou négatives jusqu’à 500Pa et la classe” R5 ” (Nmm² 300.000) pour 30 mm d’épaisseur et supporte jusqu’à 1.000Pa, à la fois avec des renforts.

Maximum ratings of tightness throughout the ductwork of low and medium pressure according EN 1507: class “C”

There is no possibility of air leaks or thermal bridges.

Avoid annoying condensation.

The combination of the excellent thermal insulation (λ=0,023 W/m·K declared according EN 12667) 12667), the low load loss (absolute roughness:

0,03mm) and the high sealing classification for low and medium pressure air ducts (EN 1507: class “C”) translates into savings of many kw energy throughout the lifecycle of the facility or LCC. (Life Cycle Cost)

Comply with the highest international requirements reaction to fire.

In June 2005 came into force and enforceable throughout the European Union (EU) Euroclass reaction to fire as the only valid and harmonized classification for all countries that form the EU and supersedes all previous test methods which are individually applied to each of the countries.

Fire reaction according EN 13501-1:

Euroclass B-s1,d0

In November 2015 we achieved certification of American Standard ASTM E84-15 “Standard Method of Test for Surface Burning Characteristics of Building Materials”. ASTM E84-15, class ”A”: FS/SD ≤25/50

The weight of the air ducts is a determining factor of safety in areas of seismic activity.

The PIR-ALU ducts weigh only ±1,1 kg/m², eight times less than traditional uninsulated metal ducts.

They apply the recommendations of the “Practical Guide to Seismic Restraint” of ASHRAE.

Especially regards the hangers and supports of the ducts and dilation joints.

The performance of materials and finished ducts are credited with tests and certificates required by the regulations, rules or standards and certifications.

The PIR-ALU air ducts can be installed inside and outside of buildings with additional protection.

In urban, industrial and marine environments.

In residential facilities, hospitals, offices, cinemas, theaters, hotels, shopping centers and supermarkets, food or pharmaceutical industries, pools or any other installation.

The coating of pure aluminium embossed 0.06 mm (60mμ) prevents air contact with insulation.

The internal insulation does not release particles upon contact with air.

Aluminium prevents the accumulation of particles and maintains hygiene in the air prevents physical health of people and prevents microbial growth.

In application of the European Standard as required by EN 13403, all PIR-ALU panels have a treatment that guarantees non-microbial growth.

The indoor air quality (IAQ) is assured. In compliance with EN 13403 of the pre-insulated PIRALU panels have the following tests and certificates relating to health, hygiene and welfare:

FACILITIES IN HOSPITALS

Complies with EN 100713 “Air conditioning in hospitals” as well as the recommendations of the ASHRAE guide “HVAC Design Manual for Hospitals and Clinics”

It is cheap and requires little expense

The economy of a ductwork begins with a simple design. Later by use practical and efficient materials.

But especially apply an appropriate transformation system of panels in air ducts.

Depending on the applied system increase or reduce runtimes, labor, materials and waste.

PIR-ALU proposes the STRIP SYSTEM to transform the pre-insulated aluminium panels in HVAC ductwork.

The system is cheap, it requires little expense and lower than normal and does not imply any difficulty or effort.

The STRIP SYSTEM teaches how to do it.

The “Protocols” are a detailed sequence of the process at different stages involving a project of HVAC ducts.

They are specially designed to facilitate the work and quality management in ductwork projects.

Four are the “Protocols” work:

In each of the “Protocols” are taken into consideration all the step by step details to follow based on compliance with regulations, rules or standards and certifications.

Very easy to use hand tools for cutting panels and ducts assembly with high productivity.

Designed especially for use and application of the STRIP SYSTEM.

The cost is reduced and facilitating fabrication providing high productivity, an excellent finish of air ducts and many other benefits.

More than thirty years making projects of pre-insulated aluminium HVAC ducts around the world allow us today to put our acquired know-how available to customers and partners.

Thanks to the know-how without great effort, skill or special ability can immediately start to use the system of assemble the ducts.

It is simple and offers no difficulty.

Enquiries, support and advice are continuous and all is done through our Smart Center.

It is the “Integrate Center for Management and Support for Pre-insulated Aluminium HVAC Ductwork Projects”.

From the Smart Center, is coordinated the innovation, technical support and exchange of know-how.

It is a service available to customers and partners.

For any questions, suggestions or requests for assistance in the Smart Center will always find the answer of confidence.